Note

Go to the end to download the full example code.

Propagation constant: DCFC#

Imports#

import numpy

from SuPyMode.workflow import Workflow, fiber_loader, Boundaries, BoundaryValue, DomainAlignment

from PyOptik import MaterialBank

import PyFiberModes

from PyFiberModes.fiber import load_fiber

from PyFiberModes.__future__ import get_normalized_LP_coupling

import matplotlib.pyplot as plt

import itertools

wavelength = 1550e-9

fiber_name = 'test_multimode_fiber'

scale_factor = 4

clad_refractive_index = MaterialBank.fused_silica.compute_refractive_index(wavelength) # Refractive index of silica at the specified wavelength

Generating the fiber structure#

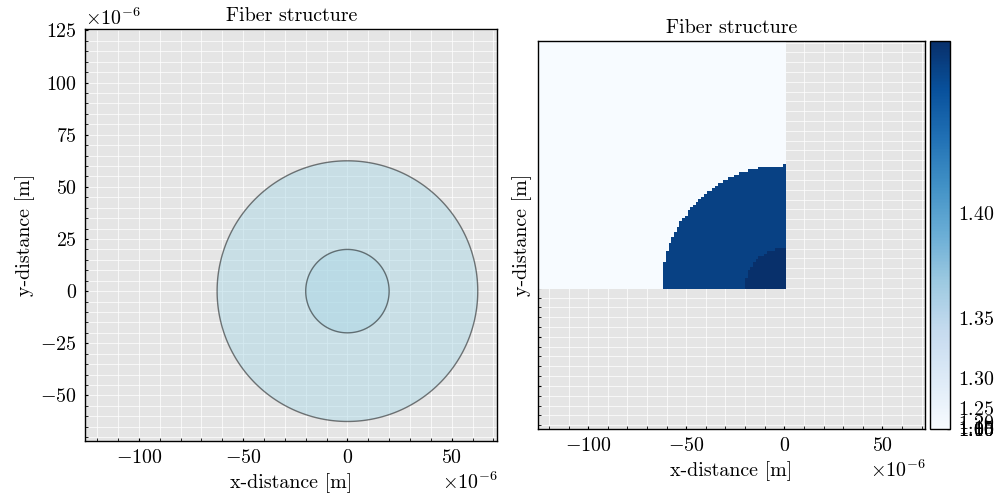

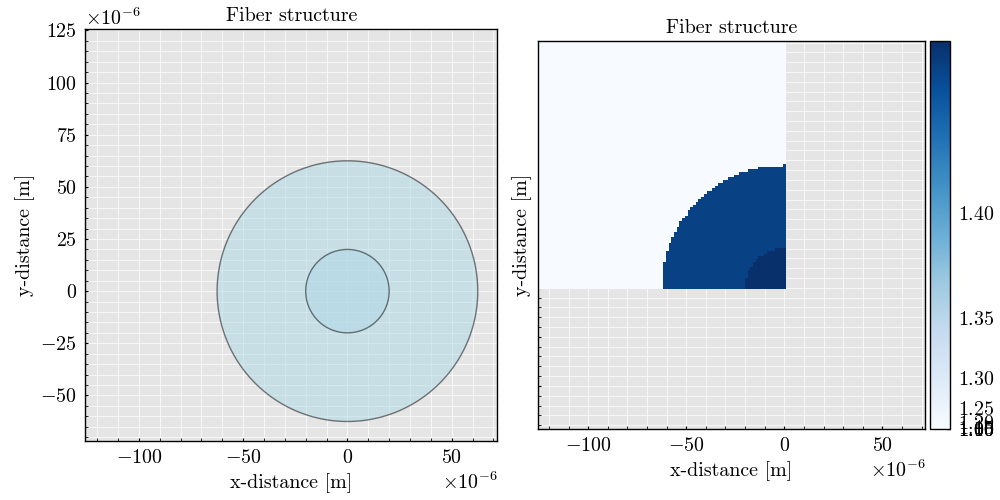

Here we define the cladding and fiber structure to model the problem

fiber = fiber_loader.load_fiber(fiber_name, clad_refractive_index=clad_refractive_index, remove_cladding=False)

fiber_list = [fiber]

Defining the boundaries of the system

boundaries = [

Boundaries(right=BoundaryValue.SYMMETRIC, bottom=BoundaryValue.SYMMETRIC),

]

Generating the computing workflow#

Workflow class to define all the computation parameters before initializing the solver

workflow = Workflow(

fiber_list=fiber_list, # List of fiber to be added in the mesh, the order matters.

wavelength=wavelength, # Wavelength used for the mode computation.

resolution=180, # Number of point in the x and y axis [is divided by half if symmetric or anti-symmetric boundaries].

x_bounds=DomainAlignment.LEFT, # Mesh x-boundary structure.

y_bounds=DomainAlignment.TOP, # Mesh y-boundary structure.

air_padding_factor=2.0,

boundaries=boundaries, # Set of symmetries to be evaluated, each symmetry add a round of simulation

n_sorted_mode=7, # Total computed and sorted mode.

n_added_mode=6, # Additional computed mode that are not considered later except for field comparison [the higher the better but the slower].

debug_mode=1, # Print the iteration step for the solver plus some other important steps.

auto_label=True, # Auto labeling the mode. Label are not always correct and should be verified afterwards.

itr_final=0.4, # Final value of inverse taper ratio to simulate

n_step=100

)

workflow.initialize_geometry(plot=True) # Initialize the geometry and plot it

workflow.run_solver() # Run the solver to compute the modes

Plotting the geometry

workflow.geometry.plot()

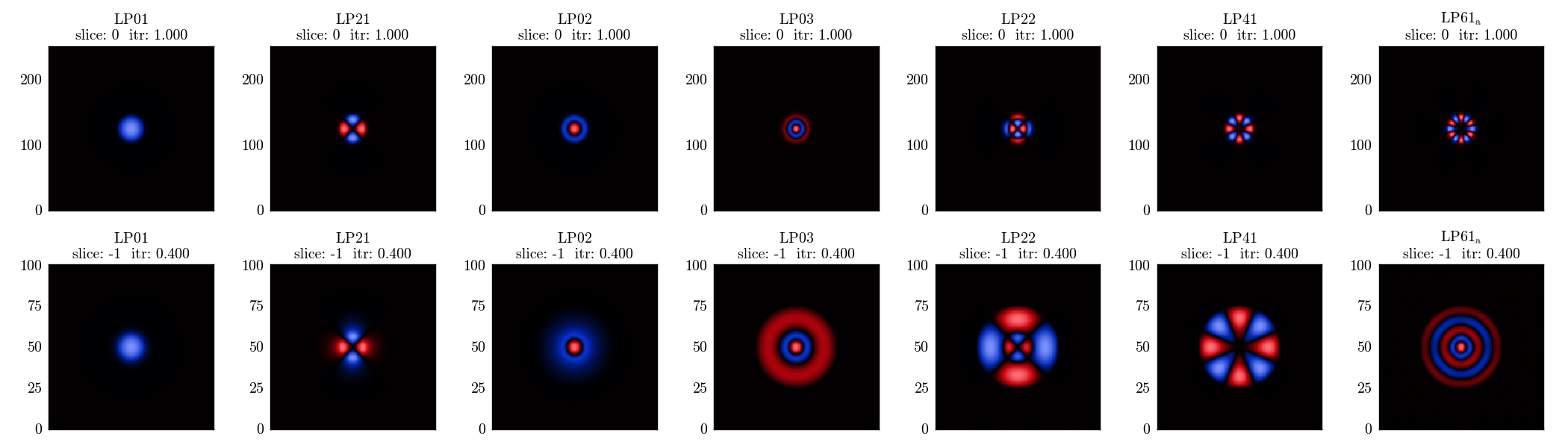

workflow.superset.label_supermodes('LP01', 'LP21', 'LP02', 'LP03', 'LP22', 'LP41')

Plotting the field distribution

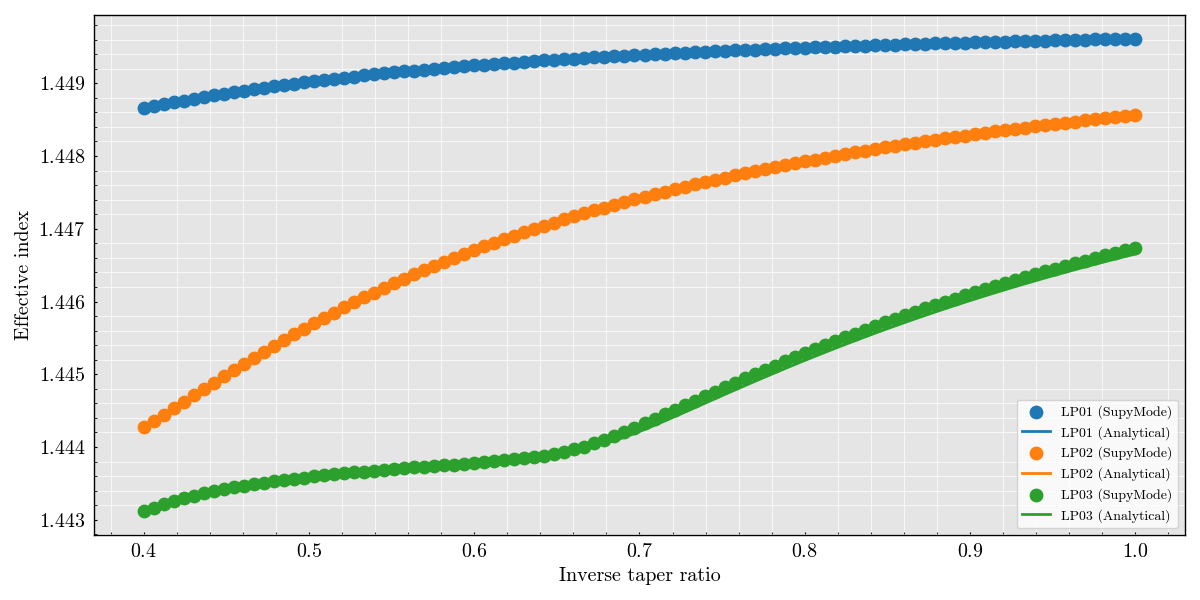

Computing the analytical values using FiberModes solver.

initial_fiber = load_fiber(

fiber_name=fiber_name,

wavelength=wavelength,

add_air_layer=False

)

Preparing the figure

figure, ax = plt.subplots(1, 1, figsize=(12, 6))

ax.set(

xlabel='Inverse taper ratio',

ylabel='Effective index'

)

def get_index_pyfibermodes(mode, itr_list, fiber):

analytical = numpy.empty(itr_list.shape)

for idx, itr in enumerate(itr_list):

tapered_fiber = fiber.scale(factor=itr)

analytical[idx] = tapered_fiber.get_effective_index(mode=mode)

return analytical

for idx, mode in enumerate(['LP01', 'LP02', 'LP03']):

color = f"C{idx}"

supymode_mode = getattr(workflow.superset, mode)

ax.scatter(

itr_list,

supymode_mode.index.data,

label=str(supymode_mode) + " (SupyMode)",

color=color,

s=80,

linestyle='-'

)

analytical = get_index_pyfibermodes(mode=getattr(PyFiberModes, mode), itr_list=itr_list, fiber=initial_fiber)

ax.plot(

itr_list,

analytical,

label=str(mode) + " (Analytical)",

linestyle='-',

linewidth=2,

color=color

)

plt.legend()

plt.grid()

plt.show()

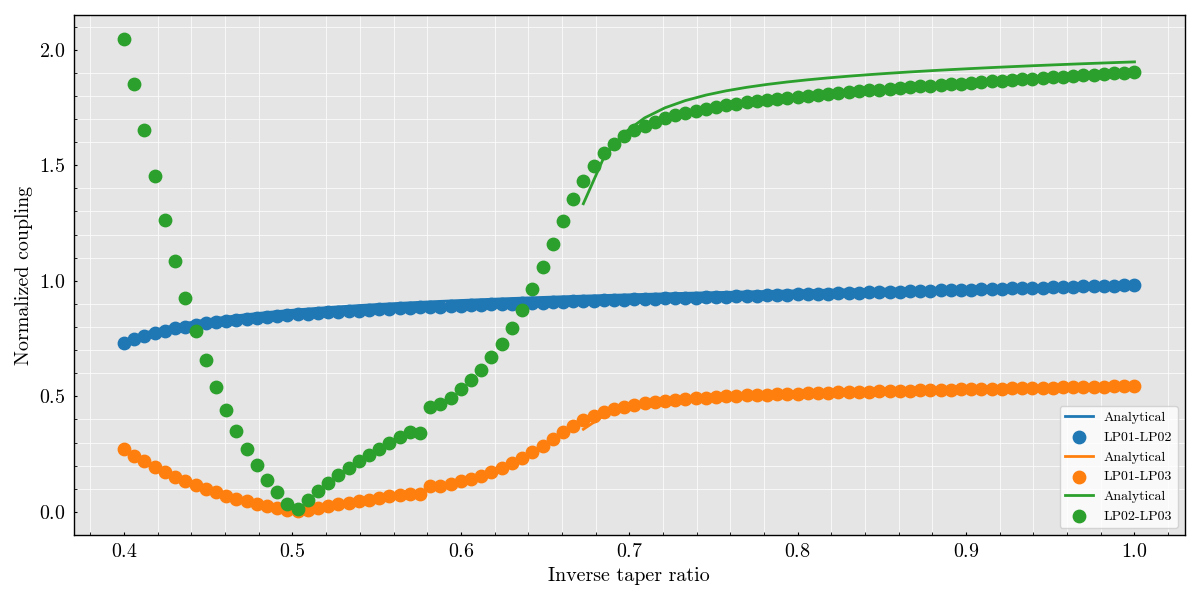

Computing the analytical values using FiberModes solver. Preparing the figure

figure, ax = plt.subplots(1, 1, figsize=(12, 6))

ax.set(

xlabel='Inverse taper ratio',

ylabel='Normalized coupling'

)

initial_fiber = load_fiber(

fiber_name=fiber_name,

wavelength=wavelength,

add_air_layer=False

)

def get_normalized_coupling_pyfibermodes(mode_0, mode_1, itr_list, initial_fiber):

analytical = numpy.empty(itr_list.shape)

for idx, itr in enumerate(itr_list):

tapered_fiber = initial_fiber.scale(factor=itr)

analytical[idx] = get_normalized_LP_coupling(fiber=tapered_fiber, mode_0=mode_0, mode_1=mode_1)

return analytical

for idx, (mode_0, mode_1) in enumerate(itertools.combinations(['LP01', 'LP02', 'LP03'], 2)):

color = f"C{idx}"

analytical = get_normalized_coupling_pyfibermodes(

mode_0=getattr(PyFiberModes, mode_0),

mode_1=getattr(PyFiberModes, mode_1),

itr_list=itr_list[::2],

initial_fiber=initial_fiber

)

ax.plot(

itr_list[::2],

abs(analytical),

label='Analytical',

linestyle='-',

linewidth=2,

color=color

)

simulation = getattr(workflow.superset, mode_0).normalized_coupling.get_values(getattr(workflow.superset, mode_1)) / (3.1415 * 2)

ax.scatter(

workflow.superset.model_parameters.itr_list,

abs(simulation),

color=color,

s=80,

linestyle='-',

label=mode_0 + '-' + mode_1

)

plt.legend()

plt.grid()

plt.show()

# -

Total running time of the script: (0 minutes 36.710 seconds)